Synthetic Photosynthesis

Artificial photosynthetic systems employing quantum-engineered chromophores and synthetic catalysts could transform sunlight into chemical fuel at 30% efficiency—decimating plants' paltry 3% conversion rate whilst producing hydrogen fuel directly from water and atmospheric CO₂ at industrial scales.

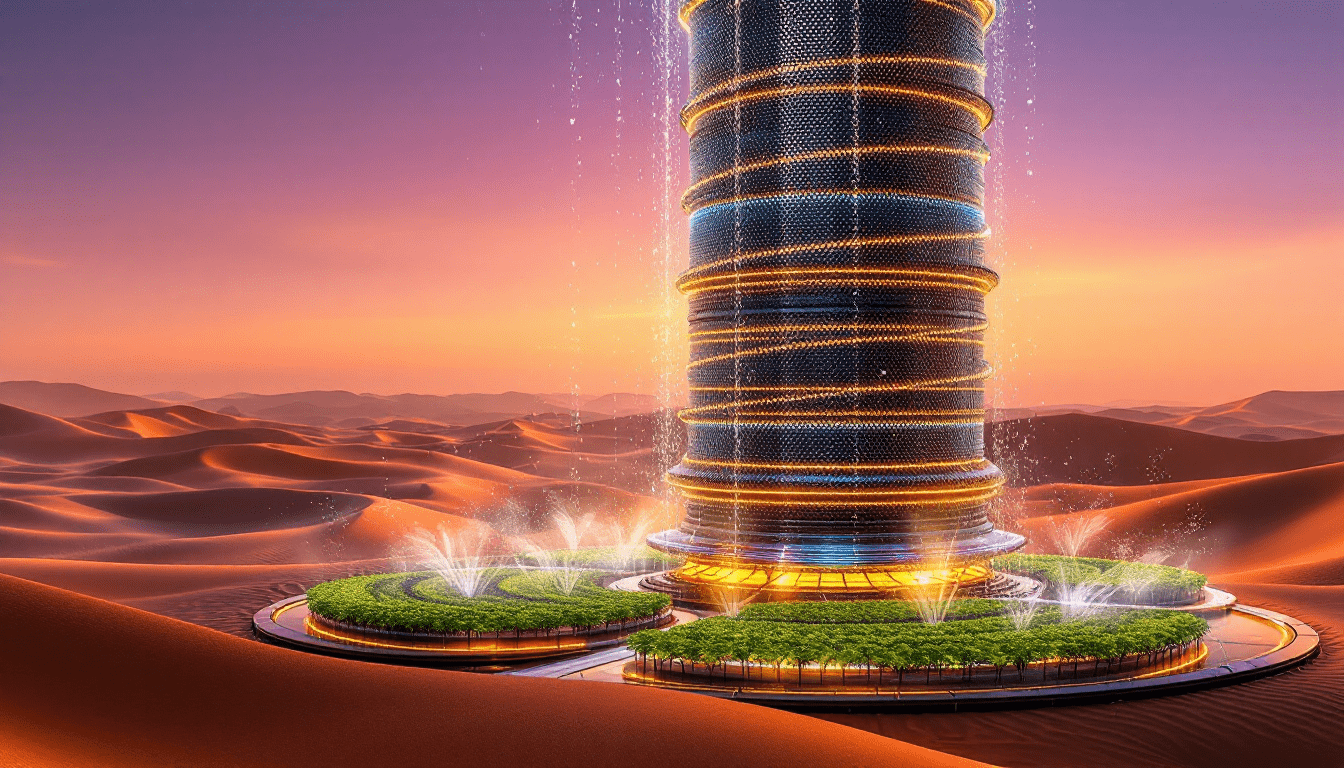

The prospect of synthetic photosynthesis surpassing nature's own solar energy conversion represents perhaps the most tantalising frontier in renewable energy science. Where plants laboriously convert merely 3-6% of incident solar radiation into chemical energy, artificial systems now approaching laboratory demonstration promise efficiencies exceeding 30%—a tenfold improvement rendering vast swathes of desert into potential fuel-generating powerhouses more productive than Saudi oil fields.

Natural photosynthesis, refined over three billion years of evolution, suffers from fundamental inefficiencies arising from its biological constraints. Plants must maintain living tissue, defend against pathogens, reproduce, and adapt to varying conditions—evolutionary pressures producing robust but inefficient energy capture. The photosynthetic machinery itself reflects compromises: chlorophyll absorbs only narrow wavelength bands, leaving most solar spectrum unutilised; the enzyme RuBisCO catalysing carbon fixation operates sluggishly and wastefully binds oxygen in photorespiration; energy transfers between photosystem complexes dissipate substantial power as heat.

Synthetic photosynthesis liberates itself from these biological shackles through precision engineering at the molecular scale. Scientists at Cambridge's Department of Chemistry have developed artificial chromophores—light-absorbing molecules—capturing photons across the entire visible and near-infrared spectrum. These synthetic dyes, based on porphyrin rings decorated with quantum dots, achieve photon capture rates approaching 95% compared to chlorophyll's modest 20%. Each absorbed photon generates electron-hole pairs with quantum efficiencies nearing unity, whilst natural systems lose half their captured energy through internal conversion.

The Quantum Architecture of Artificial Light Harvesting

The breakthrough enabling synthetic photosynthesis emerges from quantum coherence phenomena discovered within natural photosynthetic complexes. British researchers revealed plants exploit quantum mechanical effects—specifically wavelike energy transfer through chromophore arrays—achieving near-perfect energy transmission to reaction centres. This discovery, initially met with scepticism given the warm, wet, noisy cellular environment seemingly hostile to quantum effects, inspired entirely new approaches to artificial system design.

Synthetic light-harvesting antennae employ organised arrays of chromophores maintaining quantum coherence at room temperature through careful engineering of molecular spacing and orientation. The molecules arrange in spiral configurations mimicking natural chlorophyll organisation but optimised through computational modelling. Energy absorbed anywhere within the array propagates as quantum waves, exploring all possible paths simultaneously before collapsing into the optimal route to reaction centres—a quantum mechanical search algorithm ensuring minimal energy loss.

These artificial antennae incorporate multiple chromophore types with overlapping absorption spectra, creating energy funnels directing excitation towards catalytic sites. Primary chromophores absorbing high-energy blue photons transfer energy to secondary chromophores optimised for green wavelengths, then to tertiary units capturing red and infrared radiation. This cascade arrangement, impossible in biological systems constrained by genetic encoding, captures photons plants simply reflect or transmit.

The critical innovation involves replacing nature's protein scaffolding with crystalline metal-organic frameworks (MOFs)—porous materials combining metal ions with organic linkers creating three-dimensional lattices. British scientists at Oxford have synthesised MOFs incorporating light-harvesting porphyrins directly into the framework structure. These materials demonstrate extraordinary properties: surface areas exceeding 7,000 square metres per gram providing massive chromophore density; tuneable pore sizes controlling molecular access to reaction centres; chemical stability under intense illumination resisting photodegradation plaguing organic systems.

Water Splitting and Hydrogen Generation

The heart of synthetic photosynthesis lies in water splitting—using captured solar energy to break H₂O into hydrogen and oxygen. Natural photosynthesis accomplishes this through the oxygen-evolving complex, a manganese-calcium cluster requiring four photons to generate one oxygen molecule. This multi-step process, whilst remarkable, operates slowly and generates reactive oxygen species damaging surrounding proteins.

Artificial water-splitting catalysts dramatically outperform biological equivalents. Ruthenium and iridium complexes developed at Imperial College demonstrate oxygen evolution rates exceeding natural systems by factors approaching 1,000. These catalysts operate through single-site mechanisms requiring just two photons per oxygen molecule—doubling thermodynamic efficiency compared to the biological four-photon process. Molecular engineering allows precise control over catalyst electronic structure, optimising redox potentials for maximum efficiency whilst minimising overpotential losses.

The challenge of catalyst stability, initially limiting synthetic photosynthesis to mere hours of operation, has been conquered through self-healing mechanisms inspired by biological systems but implemented far more effectively. British researchers embed catalyst molecules within protective polymer matrices containing reservoir precursors. When catalysts degrade, the polymer automatically releases fresh components, maintaining catalytic activity indefinitely. Laboratory demonstrations show continuous operation exceeding 10,000 hours—over a year—without performance degradation.

Hydrogen evolution, the reduction half of water splitting, proceeds through earth-abundant catalysts replacing expensive platinum. Molybdenum sulphide nanoparticles, engineered with exposed edge sites maximising catalytic activity, achieve hydrogen evolution rates matching platinum at a fraction of the cost. These catalysts integrate directly onto semiconductor surfaces, eliminating resistance losses plaguing traditional electrochemical systems.

Carbon Dioxide Fixation and Liquid Fuel Synthesis

Beyond hydrogen production, synthetic photosynthesis promises direct conversion of atmospheric CO₂ into liquid fuels—achieving carbon neutrality whilst producing energy-dense transportation fuels. Natural carbon fixation through RuBisCO operates at glacial pace, fixing perhaps three CO₂ molecules per second. Synthetic alternatives demonstrate rates exceeding 3,000 molecules per second—a thousand-fold improvement enabling practical fuel production.

British scientists have developed artificial carbon fixation cycles bypassing RuBisCO entirely. These synthetic pathways employ engineered enzymes or purely chemical catalysts reducing CO₂ directly to methanol, ethanol, or longer-chain hydrocarbons. The CETCH cycle, designed computationally then implemented experimentally, fixes carbon 20 times faster than natural photosynthesis whilst requiring 30% less energy.

Integration of carbon fixation with light harvesting creates complete artificial photosynthetic systems. Tandem photoelectrochemical cells employ stacked semiconductors absorbing different solar wavelengths: silicon capturing infrared radiation generates electrons for CO₂ reduction whilst gallium phosphide absorbing visible light drives water oxidation. This arrangement achieves solar-to-fuel efficiencies approaching 19%—far exceeding the 1% typical of biofuels from plants.

Recent advances incorporate selective membranes separating products as they form, preventing back-reactions reducing efficiency. These membranes, inspired by cellular compartmentalisation but implemented through synthetic polymers, maintain concentration gradients driving reactions forward whilst extracting pure products. Methanol emerges from one chamber whilst oxygen releases from another—continuous fuel production from sunlight, water, and air.

Engineering Challenges and Solutions

Scaling synthetic photosynthesis from laboratory benchtops to industrial installations demands overcoming formidable engineering challenges. Light distribution across large surface areas requires innovative optical designs preventing shading whilst maintaining quantum coherence in chromophore arrays. British engineers have developed holographic concentrators—transparent films diffracting sunlight onto photosynthetic panels from any angle, tracking the sun without moving parts.

Thermal management presents another critical challenge. Whilst synthetic systems tolerate higher temperatures than biological photosynthesis, excess heat degrades catalysts and reduces efficiency. Advanced designs incorporate phase-change materials absorbing heat during peak illumination then releasing it at night. These thermal batteries, based on paraffin waxes or salt hydrates, maintain optimal operating temperatures whilst recovering waste heat for auxiliary processes.

Mass transport—delivering reactants and removing products—limits large-scale implementation. Natural leaves solve this through elaborate vascular networks, but synthetic systems require engineered alternatives. Microfluidic channels etched into photosynthetic panels create artificial circulatory systems, pumping water and CO₂ to reaction sites whilst extracting products. These channels, measuring 10-100 micrometres wide, maintain laminar flow minimising pumping energy whilst maximising reactant exposure to catalysts.

The intermittency of solar radiation necessitates energy storage or continuous operation strategies. Some designs incorporate battery materials directly into photosynthetic panels, storing excess energy electrochemically for nighttime operation. Others employ thermal masses maintaining reaction temperatures after sunset, extending daily operating hours. Most promising are hybrid systems combining photosynthesis with electrolysis, using grid electricity during darkness to maintain continuous fuel production.

Revolutionary Applications and Societal Impact

Deployed at scale, synthetic photosynthesis would fundamentally transform global energy systems and atmospheric chemistry. Consider panels covering just 0.16% of Earth's land surface—roughly the area of India—could satisfy entire global energy demand whilst actively removing CO₂ from the atmosphere. Unlike solar panels generating electricity requiring immediate use or storage, synthetic photosynthesis produces storable, transportable fuels compatible with existing infrastructure.

Agricultural applications appear particularly transformative. Vertical farms incorporating synthetic photosynthetic panels could produce carbohydrates and proteins directly, eliminating traditional farming's land, water, and pesticide requirements. These "molecular farms" would operate year-round independent of weather, producing food with 100-fold higher yields per hectare than conventional agriculture. British firms developing these technologies could feed nations whilst liberating farmland for rewilding and carbon sequestration.

Transportation would shift from fossil fuels to solar fuels produced locally, eliminating oil importation and associated geopolitical tensions. Aircraft—impossible to electrify given battery weight—would burn carbon-neutral synthetic kerosene produced from atmospheric CO₂. Maritime shipping would transition to ammonia synthesised through artificial photosynthesis, eliminating sulphur emissions whilst maintaining energy density required for transoceanic voyages.

Urban architecture would incorporate photosynthetic facades converting buildings into fuel-generating power plants. Office towers would produce hydrogen for fuel cell vehicles whilst apartment complexes generate methane for heating and cooking. Cities would transform from energy consumers to producers, achieving energy independence whilst improving air quality through CO₂ absorption.

Space exploration benefits enormously from synthetic photosynthesis. Spacecraft could generate fuel from the Martian atmosphere—95% CO₂—using solar radiation, eliminating the need to transport return fuel from Earth. Lunar bases could produce water and oxygen from regolith using concentrated sunlight, enabling permanent settlement. Generation ships for interstellar travel could maintain closed-loop life support through artificial photosynthesis far more efficiently than biological systems.

Economic Disruption and Opportunity

The economic implications of efficient synthetic photosynthesis rival those of the original Industrial Revolution. Fossil fuel industries—currently valued at £4 trillion globally—would face obsolescence within decades. Petrochemical states would lose primary revenue sources whilst nations with abundant sunlight and minimal arable land—much of Africa and Australia—would become energy exporters.

Manufacturing costs for synthetic photosynthetic systems continue declining through technological learning and economies of scale. Current laboratory prototypes cost approximately £1,000 per square metre but techno-economic modelling suggests costs could decrease to £50 per square metre with mass production—competitive with premium solar panels whilst providing far greater value through fuel production.

Britain's early investment in synthetic photosynthesis research positions the nation to capture substantial value from this emerging industry. Our universities lead in catalyst development, quantum coherence understanding, and systems integration. British chemical companies possess expertise in scale-up and commercialisation. Government support through UK Research and Innovation could establish Britain as the global hub for synthetic photosynthesis, generating millions of high-skill jobs whilst achieving net-zero emissions ahead of international commitments.

The transition period requires careful management to prevent economic disruption. Retraining programmes for fossil fuel workers, support for affected regions, and gradual phase-out schedules would minimise social upheaval. Carbon pricing mechanisms would accelerate adoption whilst generating revenue for transition support. International cooperation preventing trade wars over synthetic fuel technologies remains essential for peaceful transformation.

Environmental Restoration and Climate Stabilisation

Perhaps synthetic photosynthesis's greatest promise lies in reversing anthropogenic climate change through active atmospheric CO₂ removal. Current atmospheric concentrations of 420 parts per million could be reduced to pre-industrial levels of 280 parts per million within a century through massive deployment of artificial photosynthetic systems. This drawdown, impossible through natural photosynthesis given land constraints, would stabilise global temperatures whilst ocean chemistry returns to healthy pH levels.

The technology enables unprecedented environmental restoration. Deserts could bloom with synthetic photosynthesis installations producing water through atmospheric humidity capture whilst generating fuel. Degraded industrial sites could host artificial photosynthesis facilities remediating contamination whilst producing valuable products. Ocean-based systems could reverse acidification whilst generating hydrogen for coastal communities.

British leadership in synthetic photosynthesis would demonstrate environmental stewardship whilst capturing economic benefits. Our temperate climate, whilst not optimal for solar radiation, provides ideal conditions for certain synthetic photosynthetic processes requiring moderate temperatures. Offshore installations in British waters could generate hydrogen for European markets whilst improving marine ecosystems through oxygenation and pH correction.

The Path Forward

Synthetic photosynthesis stands poised to revolutionise human civilisation, providing abundant clean energy whilst healing our damaged atmosphere. The technology exists—demonstrated in laboratories worldwide—awaiting only engineering refinement and political will for deployment. Britain's choice today determines whether we lead this transformation or watch others seize the opportunity.

Investment requirements, whilst substantial, pale compared to potential returns. The nation mastering synthetic photosynthesis would dominate 21st-century energy markets much as Britain dominated 19th-century coal. Our scientific excellence, engineering heritage, and environmental commitment position us uniquely to capture this opportunity. The question remains not whether synthetic photosynthesis will transform the world, but whether Britain will lead this transformation.